An additional area of our business is providing services in the field of product design and SMT and THT installations for third-party customers.

- Extensive experience in the design, implementation and manufacture of electronic products,

- Modern technological lines ensuring the high quality of our manufactured products,

- An implemented ISO 9001:2008 Quality Management System,

- Short lead times for small and large production batches,

- Qualified and experienced staff,

- of the capacity to fulfil orders using entrusted components or by purchasing components on ourselves,

- Attractive installation prices

We develop and manufacture electronic products for domestic and foreign customers.

Govena Lighting offers comprehensive services

- PCB designing according to customers’ documentation

- SMT and THT installation

- Lead-free reflow soldering and wave soldering

- Testing with ICT testers

- Design and manufacture of functional testers according to customer requirements

- Creating software for processors following individual customer requirements

- The capability of the assembly of final products,

- Products packed in cardboard boxes, PET film, heat-shrinkable film

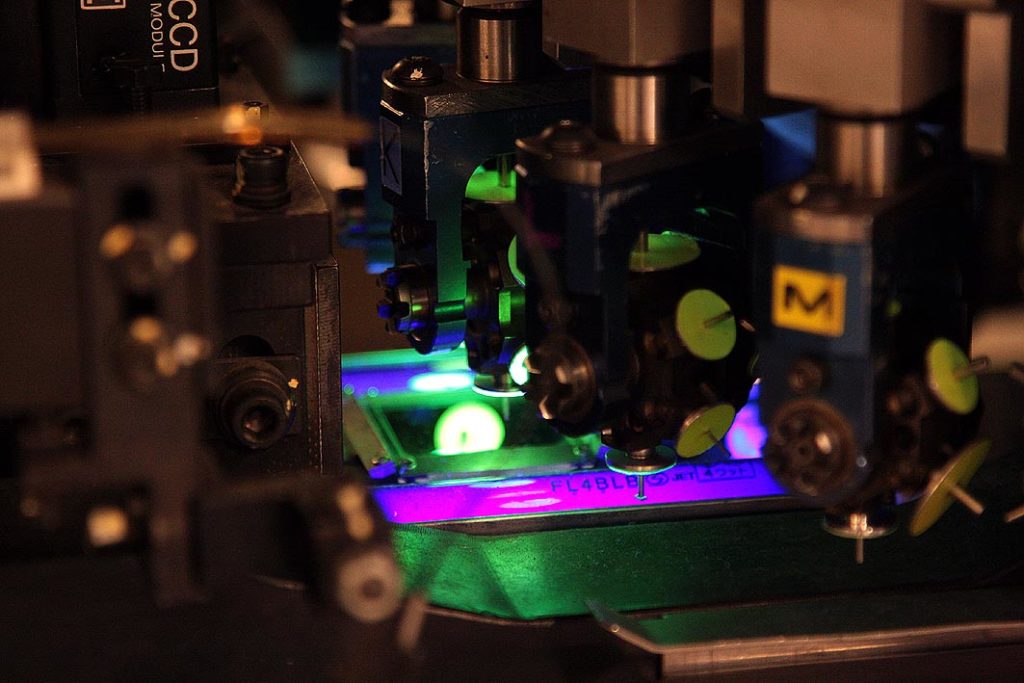

Equipment and processes

- Altium Designer – state-of-the-art system assisting the design of PCB’s, providing a complete, unified environment for the entire design proces.

- State-of-the-art testing and measurement equipment

FUJI automatic machine

- CP IP II

Efficiency 0.7sec/chip

2.8sec/IC 4.0 sec/component from the tray

Components: 0603 – 74x74mm

PCB size: max. 457x356mm

Vibration feeders and tray stations.

120 feeders with 8mm-wide strip can be plugged into our automatic unit consisting of 6 M3 modules.

- ELECTROVERT’s OmniFlex 7 oven

Min./max. width of the transport guide rails: 50.8mm / 508mm PCB support with height adjustment.

7 heating zones and 2 cooling zones.

Max. operating temperature: 350ºC

- Printing speed up to 305mm/sec. Template size: 737 x 737mm

The above devices are configured into complete assembly lines

- Assembly

- Wave soldering

ICT test

- Testers

- Test fixtures and programs developed by own test department or transferred from customers.