In the power supplies’ catalogue sheet there is the row:

“Output / RANGE OF OUTPUT VOLTAGE AT WHICH THE OUTPUT CURRENT HAS A FIXED VALUE”, e.g. for a 15W/350 mA power supply, the maximum range is from 8V to 44V.

This means the connected lamps/diodes with a total voltage between 8V and 44V will function properly.

The minimum number of LEDs which can be connected to such a power supply depends on the voltage of the diodes connected.

Since LEDs are connected in series with current supply units, their total voltage is the sum of the voltages of individual diodes.

So the above-mentioned power supply requires a connection of at least

1 x 8V LED

2 x 4V LEDs

3 x 3V LEDs

4 x 2V LEDs

What happens if the connected voltage is lower than the required minimum voltage?

LED’s light will be less bright, or will flash.

In no case, however, this this damage the power supply, thanks to its built-in protection.

Govena provides Polish products, such as electronic transformers and power supplies, to make the power supply safe.

Installation options:

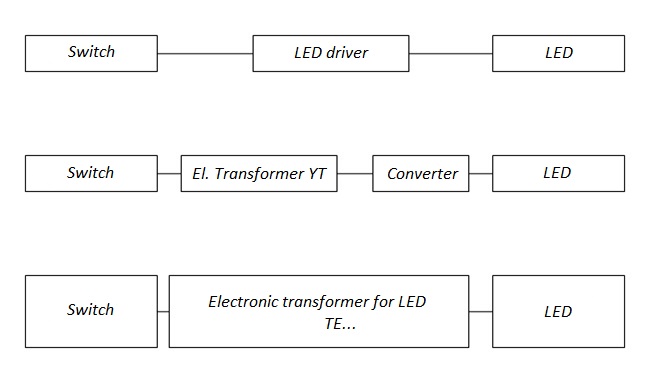

It is possible providing the technical data of the LED source contains information about the capability of supplying AC voltage with an electronic transformer.

The manufacturer of LED sources should provide information on the capability of energising LED sources directly from the transformer; otherwise it is necessary to use the KYT50 converter or use the TE electronic transformer.

There is no such device in installation terminology. This is the common name of the Govena LED electronic transformer with a built-in AC/DC converter, available in three versions

– TE-DIMM-LED-40W-12V-IP64,

– TE-DIMM-LED-60W-12V-IP40,

– TE-DIMM-LED-80W-24V-IP40.

This system is used for powering and dimming 12-volt dimmable LED sources and LED strips using an external traditional dimmer.

LED sources need to be appropriately designed to make dimming possible. The manufacturer must indicate in catalogue data sheets and on the packaging that the LED source can be dimmed.

If these are replacement lamps for halogen lamps (so-called retrofit lamps) or for conventional light bulbs, then they must be dimmable LED sources.

On the other hand, if you want to dim the LED strips, you need to use the appropriate power supply or electronic transformers for LEDs ( transforming converters).

For dimming LED sources, it is best to use RLC dimmers, although it is often the case that manufacturers of LED sources recommend the use of specific dedicated dimmers for LED sources.

In our range of products there are special dimmers for dimmable LED 230V sources. These are potentiometric PRO-250-LED dimmers (rotary-button type) and the more-advanced PRO-250-LT-LED version with an additional button (micro switch) allowing you to select one of two modes of operation and change the pre-set minimum and maximum setpoints.

PRO-250-LED and PRO-250-LT-LED dimmers are pre-set to work with the most commonly used dimmable 230V LED light sources. In the event of an unsatisfactory final effect, thanks to the MICRO SWITCH button in PRO-250-LT-LED version, it is possible to adapt the dimmer to 99% of the existing LED light sources.

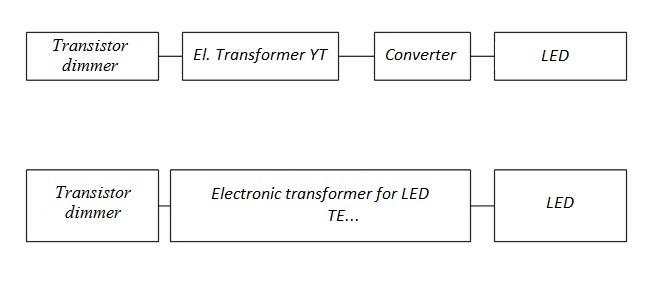

All transistor dimmers (PROI, PROT, PROPI, PROLED) operate correctly using a transformer + converter or a transforming converter (a transformer for LEDs) when powering 12VDC LED strips and 12VDC LED modules (not equipped with electronic stabilisation).

Yes: only when and if a transistor dimmer (PROI, PROT, PROT, PROPI, PROLED) is used before the transformer and the manufacturer of the source has certified the capability of using an electronic transformer to power the source.

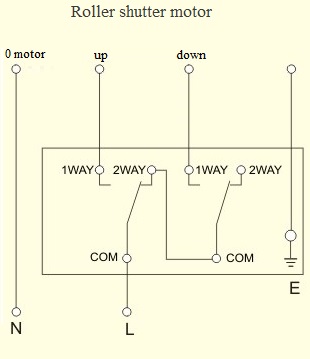

Dedicated switches are not available, but a METZ2E2…, or METZ2ET2 double switch can be used for this purpose.

The roller shutter motor should be controlled on the basis of the following diagram and installation notes.

Note:

- The motor must have properly set limit switches.

- Switching on both sections will put the motor out of operation.

This function is described below in great detail…

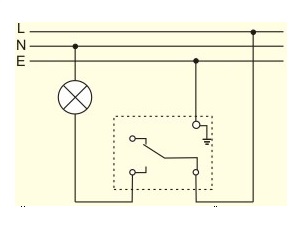

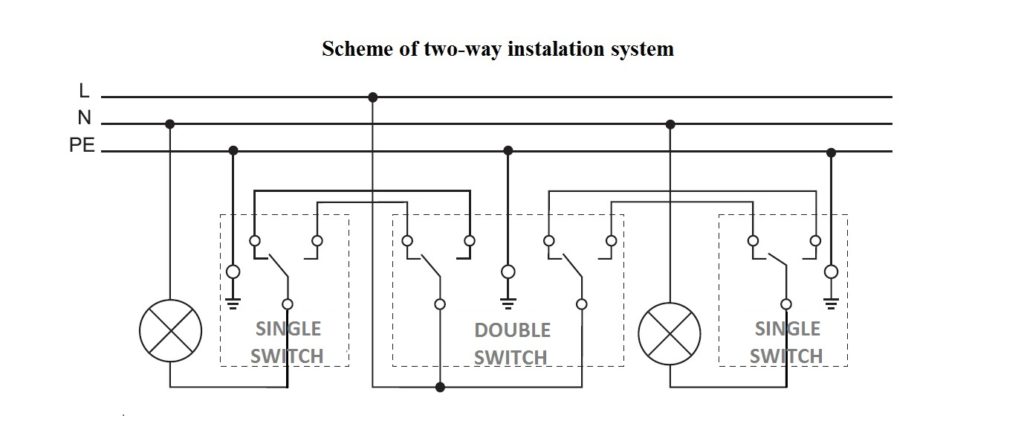

a) All Metal Line switches are multi-purpose, and can be used in two-way installations and common single circuits.

It includes the installation of a switch for a single light source.

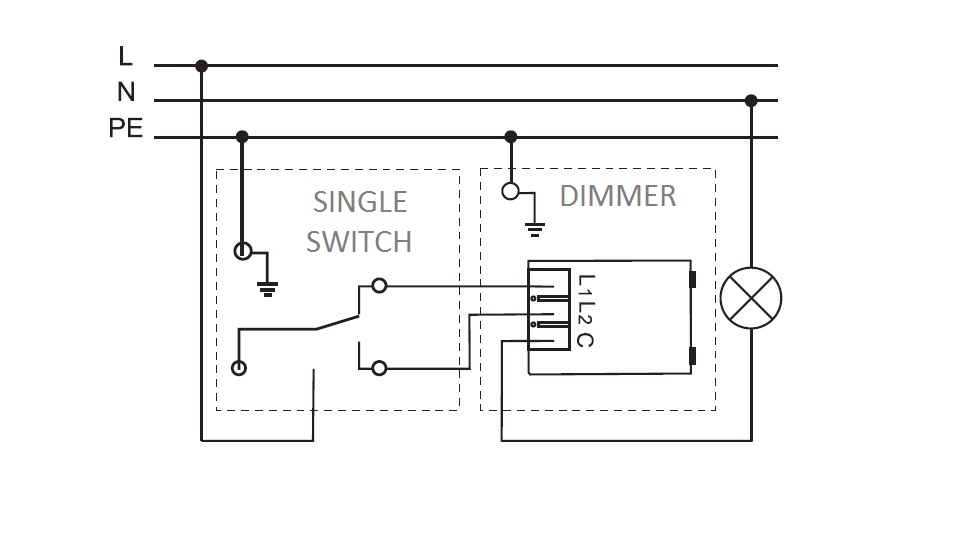

b) In addition, a two-way installation can also be carried out on the basis of one METPROP… and one METPROM… dimmer, and one switch; with this set-up you gain the extra function of dimming the stairwell lighting. A two-way installation with dimmer (the dimmer can be replaced with another switch for a traditional installation)

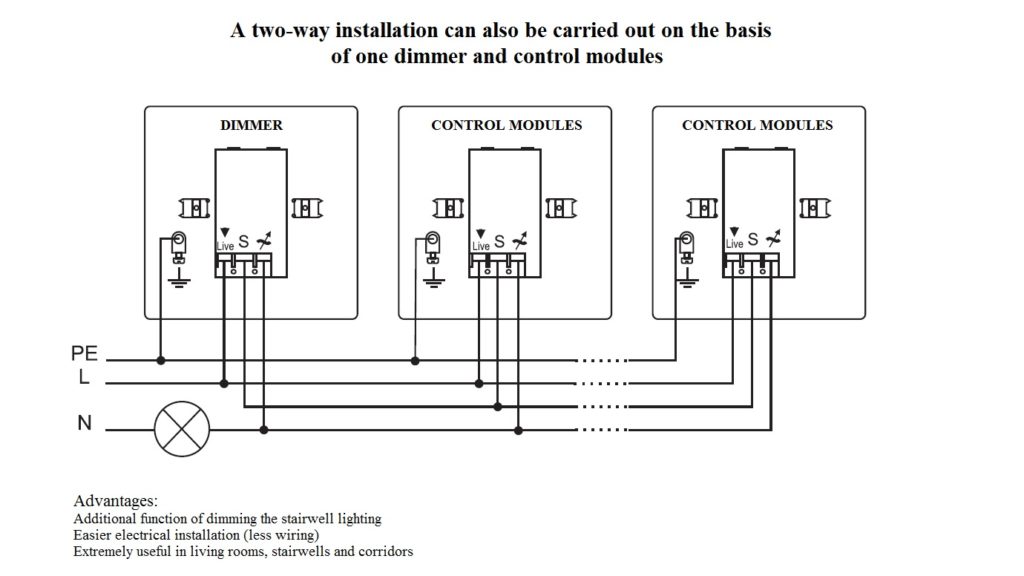

(c) The two-way installation can also be based on a METPROT… or METPROI…. dimmer, and the METPROS control module.

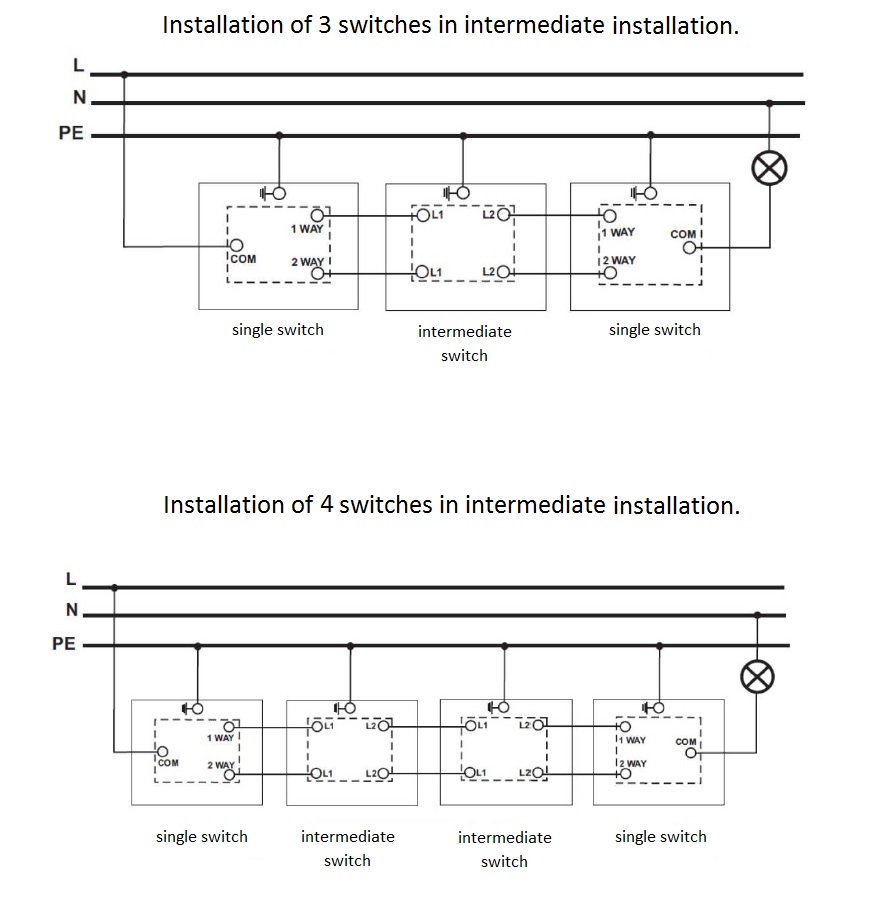

We have a dedicated solution for intermediate installation. In the Metal Line series there is METZ2E1K… the intermediate rocker switch or intermediate toggle switch METZ2ET1K…. With the use of these intermediate switches and universal Metal Line switches, which are intermediate ones at the same time, you can create extensive two-way intermediate installations, examples of which are given below…

The alternative to the intermediate system is a Govena solution based on a single METPROT… or METPROI… dimmer and an unlimited number of METPROS control modules which facilitate the installation with three cables of the existing intermediate installation.

Metal Line accessories cannot be mounted in a frame system, except for the METG1P.2… double socket, which has a double frame and box spacing as in the frame system. For the installation of the Metal Line module in the system, it is necessary to make a wider spacing of boxes, namely 85mm.

Ready-made Metal Line sets require a standard box spacing of 71 mm, relative to their axes (see figure below*). When assembling sets of single products, box axes must be 85 mm apart (see figure below**). In this case, it is recommended to use a spacer joints (e.g. from SIMET or ELSO) to facilitate the installation of the boxes in the wall.